Softeca has several years of experience with products from the Siemens Simotion and Sinamics range as well as the Simotion Scout programming platform.

We develop projects from 1 to 64 axes for power ratings from 0.37kW to 250kW.

We are able to implement complex motion control systems with electronic cams, trajectory calculations, synchronization and desynchronization of axes.

In addition to the realization of new projects, we offer troubleshooting and improvement of existing projects.

The programming languages used in Simotion Scout are ST (Structure Text), MCC (Motion Control Chart).

Below is an example of a hardware configuration with the Simotion D425 control unit used to control a cold rolling mill with real-time control and correction of the tape tension.

Example of hardware configuration with the Simotion D410-2 control unit to control a slitting shear with two asynchronous motors and a synchronous motor.

This machine is used to cut metal strips. The regulation of strip loops between each unit is automatic.

Another example of hardware configuration with Simotion D410-2 control units.

Rotary assembly machine with 9 servo presses controlled by intelligent controllers, the axes are independent of each other.

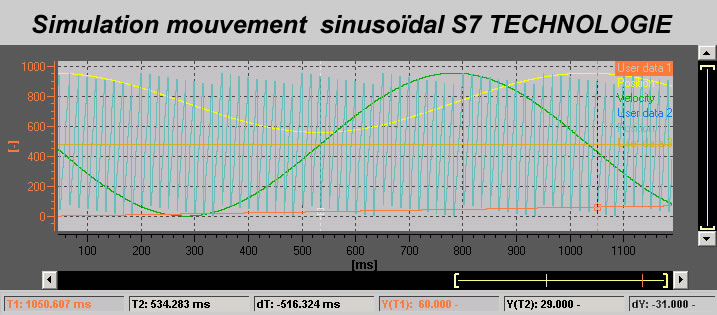

Trace analysis to determine the origin of a problem is part of our expertise, Below is an example of a trace to analyze the forces measured during a cycle on a positioning axis.

Other TechnologiesWe are able to manage a lot of differents drive from the simplest to the more complex.