Overview of the universal press system

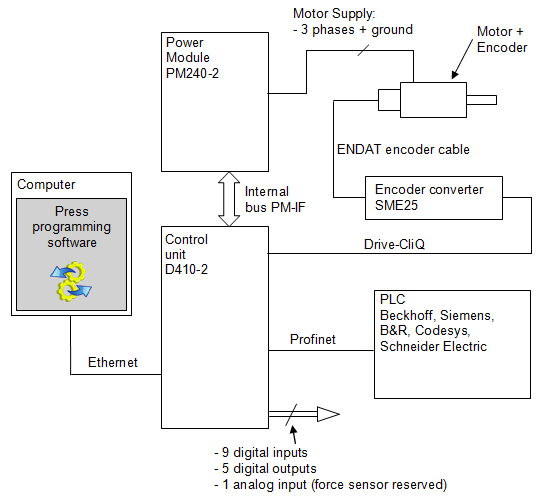

The universal press is built around a SIMOTION architecture (Siemens). This architecture is composed of the following hardware:

•D410-2 control unit specific to the axis control

•PM240-2 power part

In case the motor is not a Siemens brand and the encoder returns ENDAT signals, the following module must be added:

•Encoder feedback: SME25 encoder converter (ENDAT to Drive-CliQ)

Figure 1: Block diagram of the press in case the motor is not Siemens brand

Press programming

The press is programmed by means of MecaMotion software via an Ethernet link.

Using MecaMotion software, the following operations can be performed:

•Program different cycles (up to 254 part program).

•Modify press parameters.

•Receive and visualize the curves "Force = f(Position)".

•Define the association of user variables to inputs/outputs (physical or Profinet/Profibus).

•Compare online / offline projects.

•Check the shape of the "Force = f(Position)" curve by means of an envelope.

•View the progress of the current part program as well as the values of the user variables.

•Create production orders and save the results in a database.

•Control the press manually and execute the part programs (standalone mode).

Press control by a PLC

You can control the press with MecaMotion (standalone mode) or with a PLC and in this case, the various commands that control the press must be sent via a Profinet or Profibus link. Example :

•Execute the part program.

•Choose the press control mode (manual or automatic).

•JOG go up and go down (run on sight).

•View the errors present.

•Visualize the technological data (force, position).

•...