Association of user variables to PROFINET inputs/outputs

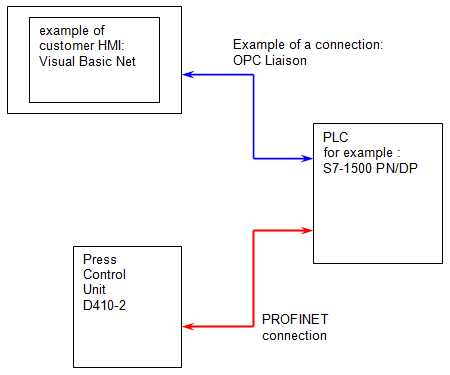

The PROFINET link allows you to send setpoints and parameters to the press from a PLC (For example: Siemens S7-1500 PN/DP) and the press can return data and results to the PLC. The reception and sending of this data can be done by the HMI of your choice.

Figure 1: Customer HMI connection to the universal press

Example of using the association of variables to PROFINET inputs/outputs: We would like to insert a component. We can send to the press via the PROFINET connection, the insertion force set point, the insertion preposition etc... At the end of the cycle, the press can return us, the final insertion force, the number of iterations and other results in LREAL format.

Note: This association of user variables to PROFINET inputs/outputs allows you to modify and read the variable values used in the press part-programs from a PLC. |

There are two types of PROFINET inputs/outputs:

•BOOL types: Transmission of values "0" (FALSE) or "1" (TRUE)

•Type DWORD (Double Word): Transmission of values of type LREAL, REAL, DINT

As explained in the "Overview of the PROFINET dialogue" topic, there are 32 possible associations for type BOOL and 50 possible associations for type DWORD.

Create the association of a variable to a PROFINET input/output

In order to associate a user variable to a PROFINET input or output, this user variable must first be created (see the topic "Declaration of user variables").

As soon as the user variable is created, please follow the steps below to associate the user variable to a PROFINET input/output.

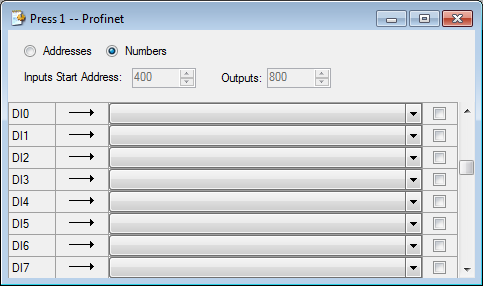

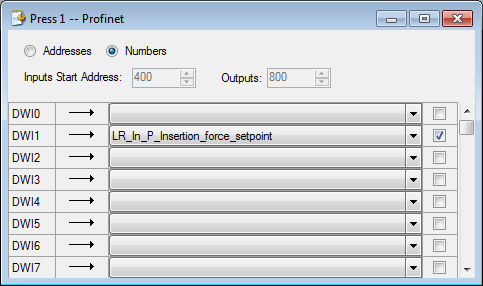

1.In the project tree, open the "hardware" tab, then double-click on the "Profinet" tab, then the window for associating variables to the PROFINET bus will be opened (see figure 2). Note: It is possible to display the inputs/outputs by number or address, if you display them by address, enter the starting addresses in order to have the same structure as on the Profinet master.

Figure 2: Window for associating variables to PROFINET inputs/outputs

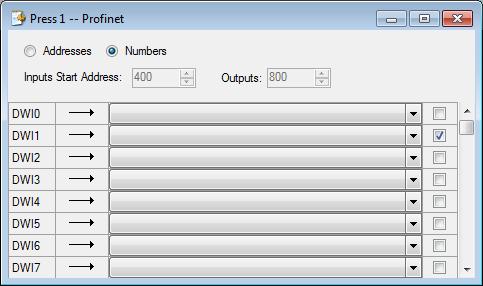

2.Select the PROFINET input or output that will be associated to the user variable. To do this, click on the "CheckBox" of the input/output in question. Attention, the inputs (DWIx or DIx) and outputs (DWOx or DOx) are seen from the press side.

Figure 3: Selection of the PROFINET input/output to be associated

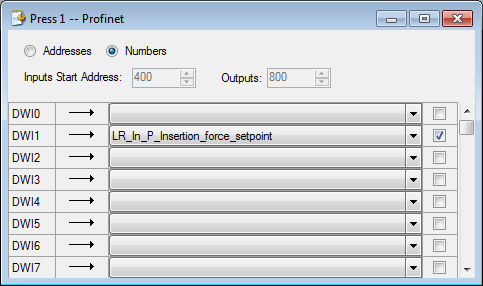

3.Select the user variable that should be associated with the PROFINET input/output in question.

Figure 4: Selection of the variable to be associated

4.For the association to be effective, load the Project into the D410-2 control unit.

Example: During a component insertion cycle, the force setpoint is a parameter that the operator must be able to change. This force command is sent to the press from the PLC, via a PROFINET connection. In Figure 5, the value of the "force" of the "Stop on force" control comes from a variable called "LR_In_P_Insertion_force_setpoint". This variable is associated with a PROFINET input, so that the force setpoint can be sent from the PLC.  Figure 5: Exemple de programme pour insertion en force Association of the variable "LR_In_P_Insertion_force_setpoint" with the Profinet inputs "DIW1". (figure 6)  Figure 6: Association of the "Insertion force setpoint" variable with a PROFINET input |