"Position measurement" control instruction

This instruction is used to record the position of the axis when the precision switch is operated.

The purpose is to be able to measure the reference of a part to perform the offset of the envelope or to have a starting position to achieve an insertion.

This function can be used with a maximum press velocity of 10mm/s.

Use of the instruction

This instruction must be before the positioning in which you want to measure.

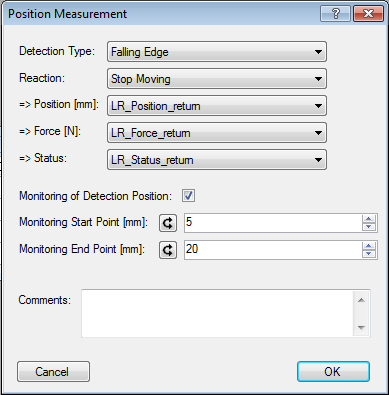

Figure 1: Parameters of the instruction position measurement

Below is a list of the instruction's input and output parameters:

Parameter name |

Declaration |

Type of data |

Default value |

Description |

|---|---|---|---|---|

Detection type |

Input |

-- |

Falling edge |

Detection type, falling edge or rising edge |

Reaction |

Input |

-- |

Stop moving |

Reaction after measurement, stop moving or continue moving |

Position [mm] |

Output |

LREAL |

-- |

Position of the axis measured at the time of detection |

Force [N] |

Output |

LREAL |

-- |

Force measured at the time of detection |

Status |

Output |

Enum [Position measurement status] |

-- |

Status of the measurement function (see description below) |

Monitoring of detection position |

Input |

-- |

-- |

Perform detection only in a position area |

Monitoring start point [mm] |

Input |

LREAL |

0[mm] |

Detection start position |

Monitoring end point [mm] |

Input |

LREAL |

0[mm] |

Detection end position |

Table 1: List of instruction parameters

Detail of the parameters to be filled in for this function:

•Detection type: Falling edge if you want to record the axis position when the sensor is pressed or rising edge if you want to record the axis position when the sensor is released (up axis).

•Reaction: Stop moving or continue moving after switching the sensor.

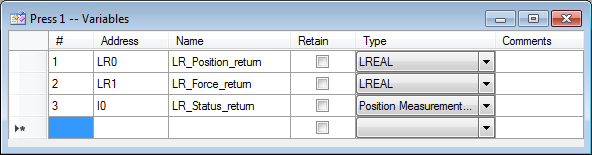

•Return variables : The position and force feedback variables must be of the "LREAL" type and the state feedback variable must be of the "position measurement status" type. The possible status are: 1 = Waiting for the sensor to switch (the measurement function is active), 2 = The measurement sensor has switched, 3 = The measurement is completed with error (the measurement could not be performed).

Figure 2: Declaration of variables

If necessary, you can perform this measurement within a certain position area of the axis. To do this, check the "monitoring of detection position" box and enter a start and end value for the area in[mm]. If you want to give the start and end position of the area using variables, they must be in LREAL format.

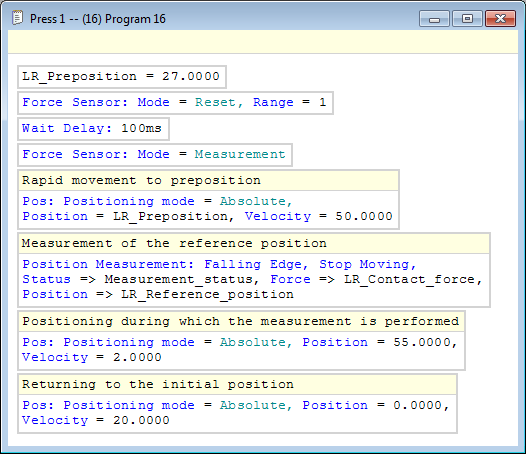

Example of use: We want to measure a reference position with the precision switch. We perform the measurement at low speed to obtain high accuracy. In the example below, we move to the preposition at high speed and then measure at low speed. When the precision switch switches, the actual position of the axis is stored in the "LR_Reference_position" variable.  Figure 4: Example of using the position measurement instruction |